Our

Services

The Vinicola San Nazarowinery in Pegognaga, province of Mantua, spreads over a total area of 30.000 square meters. Its storage capacity has steadily increased over time up to the current volume of 230.000 hectolitres.

The “historic” area of the winery has a capacity of 50.000 hectolitres thanks to concrete tanks vitrified with alimentary epoxy resins, which are partly underground in order to keep the internal storage temperature constant throughout the year.

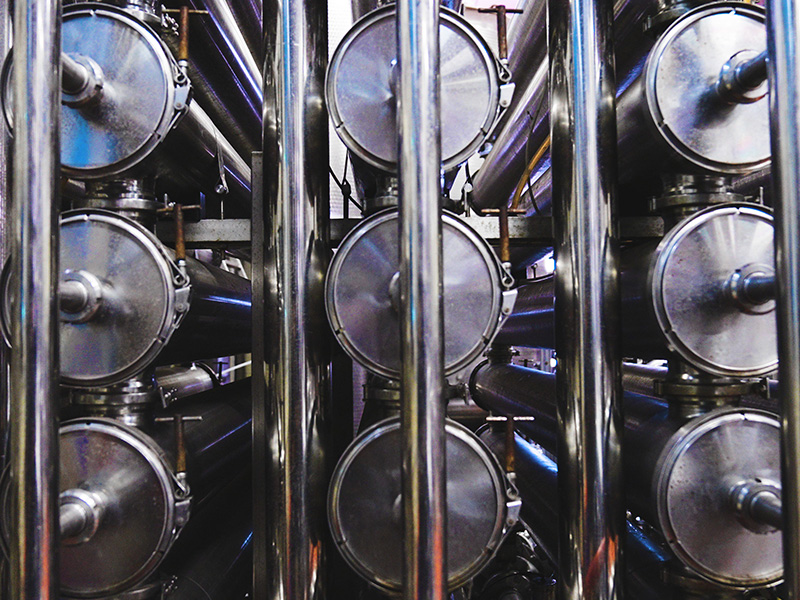

Tanks in AISI 316 stainless steel have been installed around the central building, most of which are equipped with jacketed heat exchangers to cool or heat products in summer and winter - the installed refrigerators can develop 1 million frigories.